+91-79045 61980 | Located in Chennai, TN

![Hydraulic Seamless Pipe Grade [And Materials] 1 Hydraulic Seamless Pipe Grade](https://mlfkxaygshwm.i.optimole.com/w:896/h:470/q:mauto/f:best/https://hydraulicpipes.in/wp-content/uploads/2023/09/image-6.jpg)

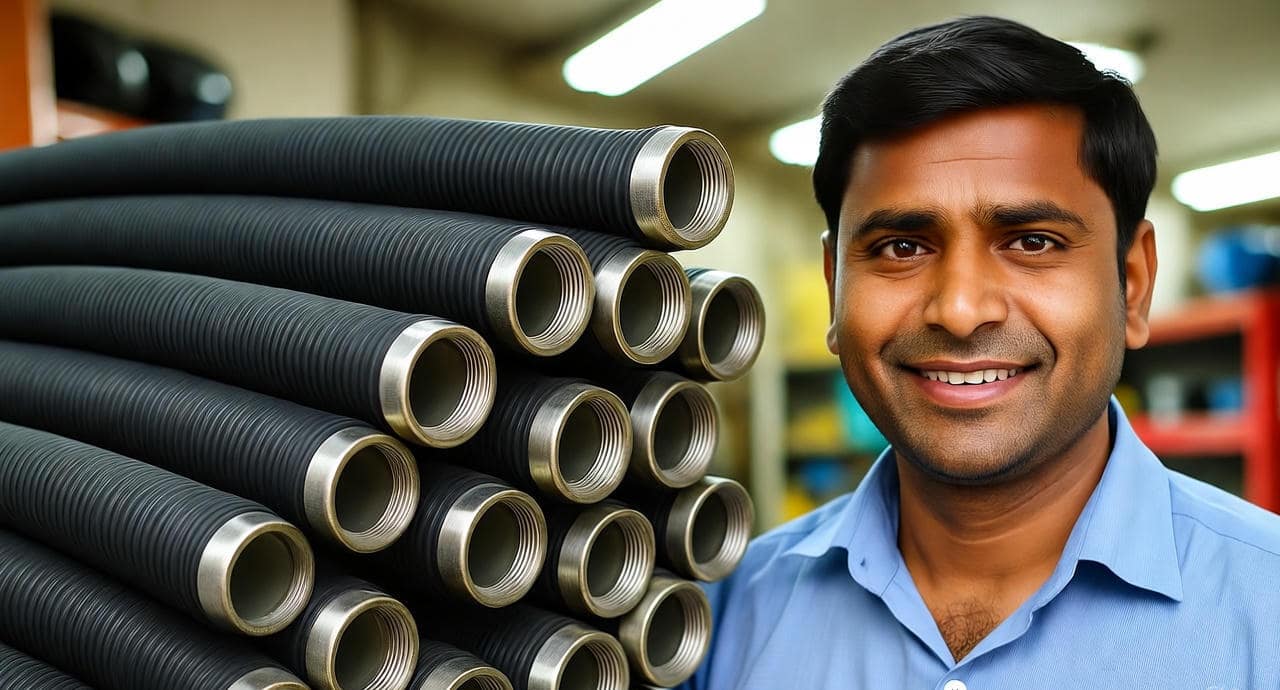

Hydraulic Seamless Pipe Grade [And Materials]

Hydraulic Seamless Pipe Grade and Materials used These Hydraulic Seamless Pipe Grades have different types,…

+91-79045 61980 | Located in Chennai, TN

Welcome to our knowledge hub on hydraulic pipes and seamless tubes. Here we share insights, industry updates, and practical tips to help you understand fluid systems better and choose the right solutions for your business.

![Hydraulic Seamless Pipe Grade [And Materials] 1 Hydraulic Seamless Pipe Grade](https://mlfkxaygshwm.i.optimole.com/w:896/h:470/q:mauto/f:best/https://hydraulicpipes.in/wp-content/uploads/2023/09/image-6.jpg)

Hydraulic Seamless Pipe Grade and Materials used These Hydraulic Seamless Pipe Grades have different types,…

Have you ever thought how big machines lift heavy load or how hydraulic system works…

Have you ever tried to explore about Stainless Steel Seamless Tubes and Applications? When we…

The GBK (Geglättet, Biegefähig, Kaltgezogen) annealing process is a special type of heat treatment used…

The manufacturing of seamless tubes for hydraulic purpose is a very careful and detailed work.…

The seamless tubes manufacturing process is a careful and detailed process. It needs skill, proper…

Have you ever thought how oil or gas move through such long pipeline without bursting…

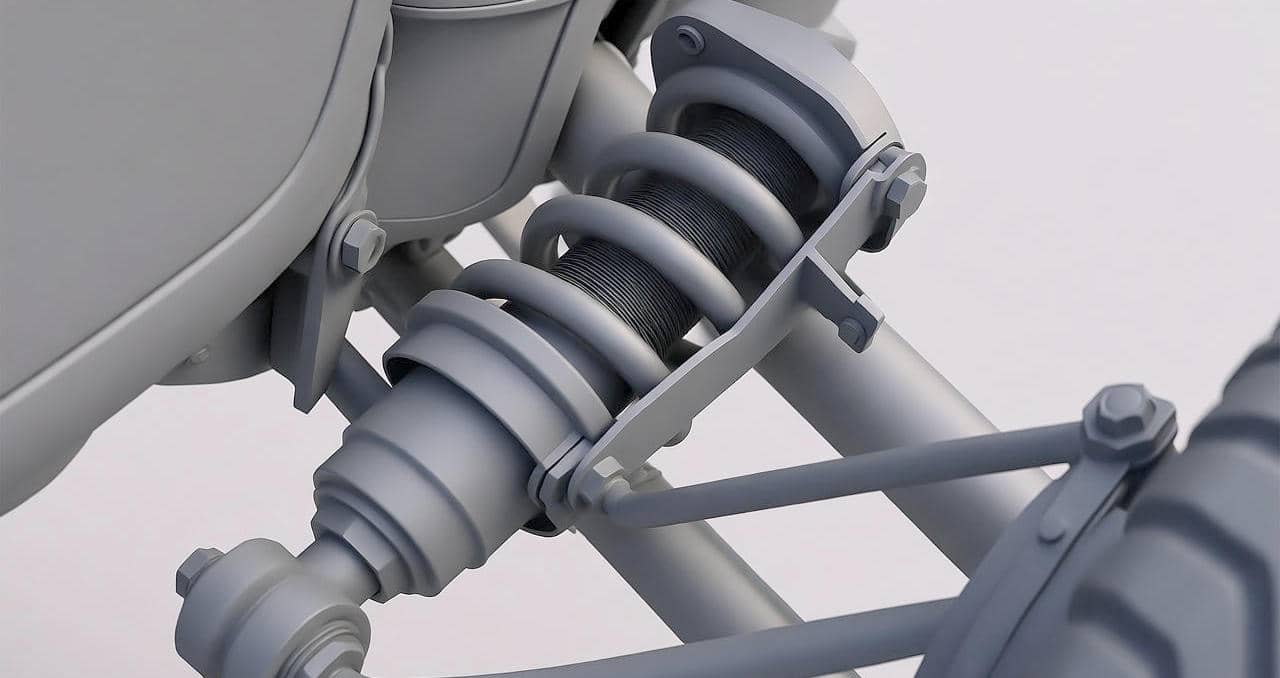

Automobile body and chassis is like backbone of vehicle. It is giving the structure, strength…

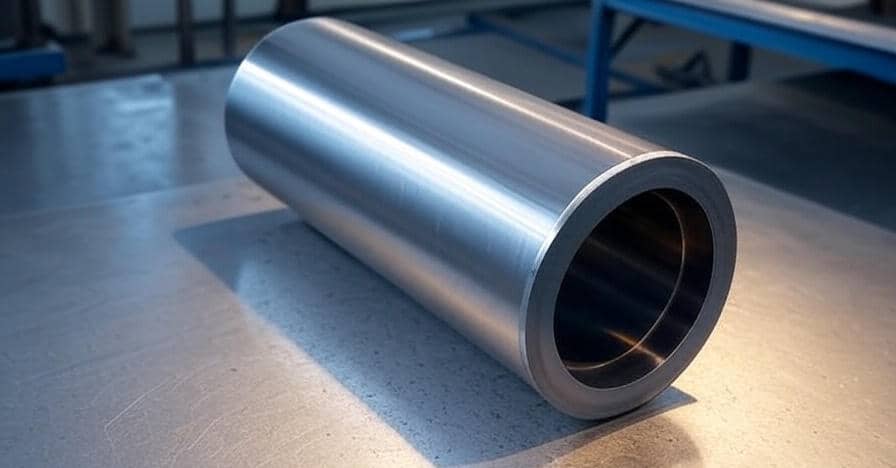

Seamless hydraulic pipes are rigid tubes made mainly from carbon steel, usually low carbon type,…

Hydraulic seamless pipe is one of the most important part in hydraulic systems today. These…

A seamless tubes and pipes are hollow cylindrical product which is used in many industries…

Heat treatment is one of the most important step in making of seamless hydraulic tube.…

Have you ever thought how oil, gas or steam move inside big machines and power…

In today’s fast moving world, automotive industry depend heavily on strong, reliable, and long lasting…

Hydraulic Seamless Tubes in Hydraulic System is backbone of modern industry. It gives power to…

Every vehicle we see on the road runs smoothly because of its suspension system. It…