+91-79045 61980 | Located in Chennai, TN

Use of Seamless Steel Tubes in Automotive Industries

In today’s fast moving world, automotive industry depend heavily on strong, reliable, and long lasting materials. Every component inside a vehicle must perform well under high stress and different road conditions. Among these, seamless steel tubes have emerged as one of the most dependable materials.

Whether it is in exhaust systems, suspension structures, or fuel lines, these tubes play a very crucial role.

Seamless steel tubes are produced without any welded joints, which gives them higher strength and uniformity.

They can withstand pressure, heat, vibration, and even corrosion. This unique combination of properties makes them highly suitable for various automobile parts.

In this article, we will study in detail the use of seamless steel tubes in automotive industry, their advantages, and why they are preferred over other materials.

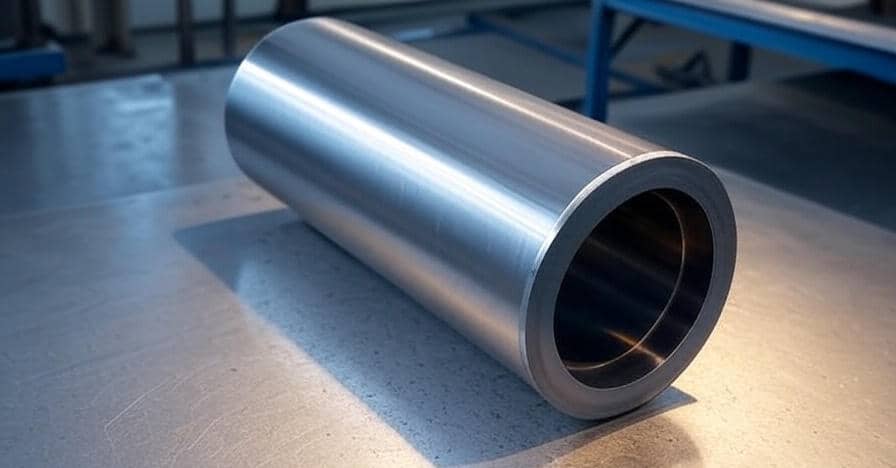

What are Seamless Steel Tubes

Seamless steel tubes are hollow cylindrical shapes made from solid steel billets. They are produced through processes like extrusion or rotary piercing. Unlike welded tubes, there are no seams or weak points in their structure. This gives them:

-

Better strength and fatigue resistance

-

Higher durability under stress

-

Smooth internal surface that improves flow

These characteristics make them ideal for high pressure and high performance applications. In vehicles, where safety and efficiency are always top priority, seamless steel tubes provide confidence to both engineers and manufacturers.

Applications of Seamless Steel Tubes in Automotive Industry

Exhaust Systems

The exhaust system of a vehicle is responsible for carrying harmful gases away from the engine and reducing their impact on environment. Exhaust pipes must work under very high temperature and corrosive conditions. Seamless steel tubes are perfect for this role because they have high thermal resistance and do not fail easily under continuous heat cycles.

In modern cars, especially turbocharged and sports models, exhaust temperature goes much higher compared to normal vehicles. Only seamless steel tubes can manage such harsh performance conditions. Their durability also ensures that exhaust systems last longer and require less frequent replacement.

Suspension Systems

Suspension is the backbone of ride comfort and vehicle stability. It absorbs shocks from the road and ensures smooth driving experience. Parts like control arms, tie rods, and sway bars must be tough enough to handle continuous stress.

Seamless steel tubes are widely used in suspension because of their strong yet flexible nature. Unlike aluminum or carbon fiber, they do not crack easily when exposed to sudden jerks. They also resist fatigue, meaning that even after thousands of kilometers, they maintain their performance. This is why car makers trust seamless steel tubes for suspension design.

Fuel Lines

Fuel lines carry petrol or diesel from the tank to the engine. The material used for fuel lines must be resistant to corrosion and leakage because even a small defect can cause major safety risk. Stainless seamless steel tubes are often chosen for this job.

They offer smooth internal surface for fast and uninterrupted fuel flow. They also resist rusting when exposed to gasoline or diesel. This ensures long term safety of the vehicle. Another advantage is that steel tubes do not react with fuels, unlike some plastic pipes, which makes them more reliable in critical applications.

Advantages of Seamless Steel Tubes in Automobiles

The reason behind popularity of seamless steel tubes lies in their numerous advantages:

-

High Strength – They can handle heavy loads and high pressures.

-

Corrosion Resistance – They do not rust or wear out quickly when exposed to fuels and environmental conditions.

-

Lightweight with Strength – They provide durability without adding too much weight to the vehicle.

-

Temperature Resistance – Can withstand very high heat, suitable for exhaust systems.

-

Long Life – Their fatigue resistance ensures that they remain dependable for years.

These advantages not only improve vehicle safety but also reduce maintenance costs, making them beneficial for both manufacturers and customers.

Seamless Steel Tubes vs Other Materials

Many alternative materials like aluminum, copper, or plastic are sometimes used in automotive systems. But seamless steel tubes are preferred due to their balanced properties.

-

Aluminum is lightweight but lacks durability under high stress.

-

Copper has good corrosion resistance but is costly and less strong.

-

Plastic is cheap but cannot withstand high temperature or pressure.

Seamless steel tubes stand in between, offering strength, cost effectiveness, and long service life. This balance is why automobile manufacturers trust them for critical components.

Growing Demand in Automotive Sector

With increasing demand for high performance vehicles and stricter emission norms, the role of seamless steel tubes is growing more important. Modern exhaust systems require tubing that can handle extreme heat while staying corrosion free. Similarly, advanced suspension systems depend on strong yet flexible material for safety.

Electric vehicles also use seamless steel tubes in cooling systems and structural support. Even though EVs do not need fuel lines, their battery cooling system benefits from the properties of seamless tubing.

Hence, the demand will not reduce but actually expand into new areas.

Challenges and Future Prospects

Like every material, seamless steel tubes also face some challenges. The cost of production is higher compared to welded tubes. They also require advanced manufacturing facilities. However, with technological improvements, these costs are coming down.

In the future, new grades of steel with improved corrosion resistance and lighter weight will make seamless tubes even more attractive. Industries are also experimenting with coatings and treatments that can extend their lifespan further.

Summary

Seamless steel tubes play a very vital role in modern automotive industry. They are used in exhaust systems for heat resistance, in suspension systems for strength and fatigue resistance, and in fuel lines for corrosion protection. Their advantages like durability, temperature resistance, and cost effectiveness make them the first choice of engineers.

The use of seamless steel tubes in automotive industry is not just about tradition but about necessity.

Their ability to combine strength, durability, and safety makes them irreplaceable in many parts of a vehicle. Whether it is a high performance sports car, a family sedan, or even an electric vehicle, seamless steel tubes continue to support smooth performance.

In coming years, as vehicles become more advanced, the importance of these tubes will only increase further.

![Hydraulic Seamless Pipe Grade [And Materials] 2 Hydraulic Seamless Pipe Grade](https://mlfkxaygshwm.i.optimole.com/w:896/h:470/q:mauto/f:best/https://hydraulicpipes.in/wp-content/uploads/2023/09/image-6.jpg)