+91-79045 61980 | Located in Chennai, TN

Applications of Seamless Tubes in Automotive Suspension Systems

Every vehicle we see on the road runs smoothly because of its suspension system. It helps in maintaining balance, comfort, and safety while driving on uneven roads. The suspension system makes sure the vehicle tyre remain in contact with the ground and the driver has full control even during turns or brakes. Seamless tubes are very important parts inside these systems. They give strength and stability to many suspension components. Without them, the system will not perform efficiently or last long.

Types of Suspension Systems

There are mainly two kinds of suspension systems that we find in automobiles today.

Independent suspension is the one where each wheel moves separately. It is used in most modern cars because it provides smoother ride and better control. The other one is dependent suspension, where both wheels are connected to one system. This is mostly seen in old models or in heavy pickup vehicles.

In simple words, independent system gives comfort, and dependent system gives strength. Both have their own importance depending on the type of vehicle and its usage.

Main Components in a Suspension System

A typical suspension system is made of many small but important parts that work together.

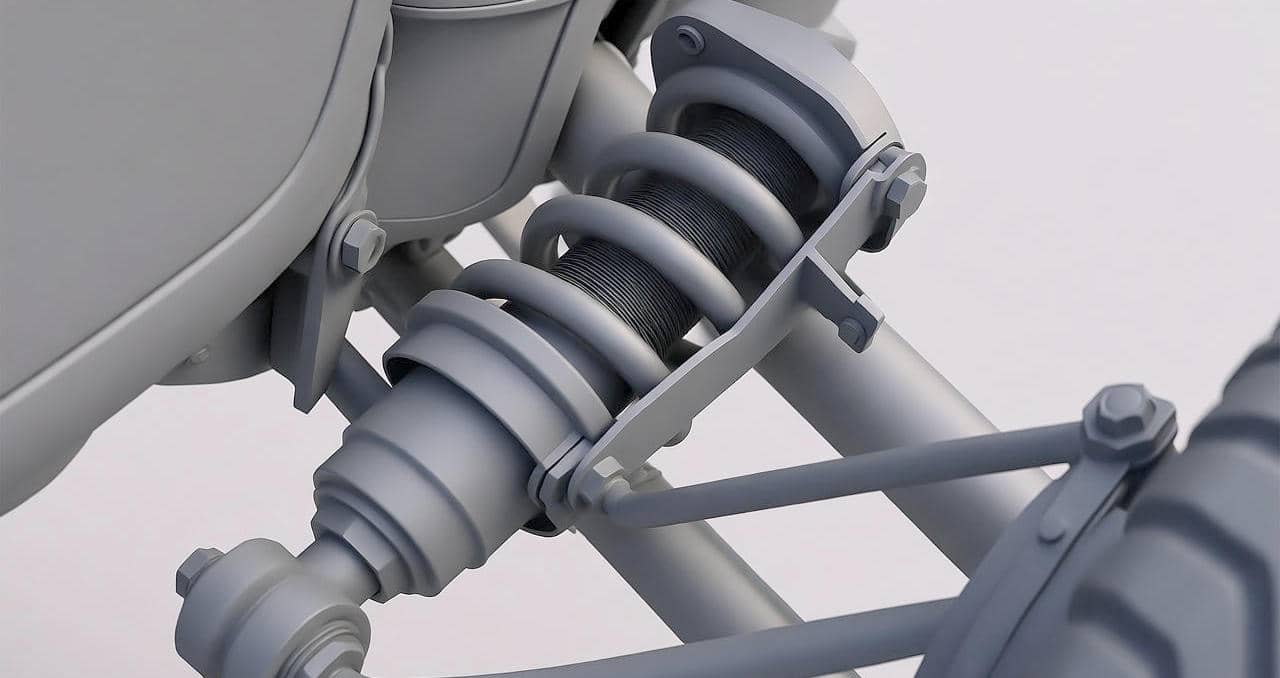

Springs are the first ones. They help in absorbing shock when a vehicle passes over bumps. There are coil springs and leaf springs depending on the model.

Then comes dampers or shock absorbers, which control how the springs move up and down. They help the car remain stable.

Control arms are like connectors between the wheels and the main vehicle body.

You will also find bushings and bearings, which help reduce friction.

At last, there are sway bars that keep the body from rolling too much while turning at high speed.

Role of Seamless Tubes in Suspension Systems

Seamless tubes are the heart of many of these components because they can handle high stress, pressure, and twisting movement.

In control arms, seamless tubes provide strength and flexibility. Since they don’t have any weld joints, they don’t crack or deform easily.

In strut tubes, they act as the main structure which holds the damper in place. These tubes give the right amount of rigidity to bear road shocks and weight of the vehicle.

Stabilizer bars, also known as sway bars, are made using seamless tubes to prevent the car from tilting too much while taking turns.

Even tie rods, which are responsible for steering, are made of seamless tubes because they can tolerate continuous pulling and pushing force during driving.

Advantages of Seamless Tubes in Suspension Systems

When we use seamless tubes in suspension parts, the performance becomes more reliable and safe.

-

They have high tensile strength, which means they don’t break or deform under heavy pressure.

-

Because there is no welding, they have uniform thickness, giving smooth and even performance.

-

These tubes can bear continuous vibration without fatigue or cracks.

-

The precision in size helps in perfect fitting, which improves the suspension alignment.

-

They last longer and require very less maintenance.

Because of these benefits, all modern car manufacturers prefer using seamless tubes for their suspension and steering components.

To conclude

From heavy trucks to small cars, all vehicles depend on seamless tubes for strong and efficient suspension systems. They not only make the ride comfortable but also improve safety and control. The absence of weld joints gives them high durability and long service life.

So, next time when we see a car running smoothly even on a rough road, we should remember that strong seamless tubes inside the suspension are silently doing their job — keeping the journey stable, safe, and comfortable.

![Hydraulic Seamless Pipe Grade [And Materials] 4 Hydraulic Seamless Pipe Grade](https://mlfkxaygshwm.i.optimole.com/w:896/h:470/q:mauto/f:best/https://hydraulicpipes.in/wp-content/uploads/2023/09/image-6.jpg)